The utilities and society prioritize sustainability and the sustainable infrastructure has never been better. Even the pad mounted transformer is facing the green revolution, that's why the modern deigns is combining smart materials and engineering to reduce the ecological impact on appliance's life process, explaining that solidity and environmental protection can go at the same time. YAWEI TRANSFORMER are devoted to incorporating sustainable practices, we make our pad mounted transformer not only for intelligence but also with big respect on our planet. These are the guidelines about our sustainable design that are now making a new standard.

Biodegradable Ester-Based Insulating Fluids Instead of Mineral Oil

The most important eco-friendly progress is shifting away from base oil. The modern transformer are growing more and more filled with biodegradable natural esters. In rapid biodegradation, we can biodegrade by over 90% in just 28 days. Higher fire safety can enhance well-being of community and utility person.

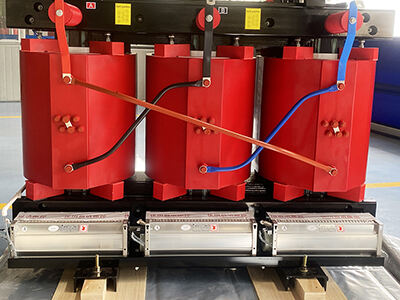

Recyclable Steel Tanks and Aluminum Windings

Circular economy approach is important to environmental design. The materials we used on making our transformer are 100% recyclable. We use recyclable steel tanks are constructed from high-tensile steel and 100% recyclable. Many manufacturers and even YAWEI allow electromagnetic wire made from aluminum because it has less energy intensive than copper.

Energy-Efficient Cores to Reduce Carbon Footprint Over Lifecycle

The biggest impact on the environment happen because of the energy that's been wasted over 25 to 40 years operational life. Managing this using high efficiency work is dominant. Using high-level core steel, modern transformers can accomplish breathtaking lower no load losses. The reduction of wasted energy will go directly in greenhouse and the energy and carbon savings will go high achieving more powerful sustainability.

Leak-Proof Containment Systems to Protect Soil and Groundwater

Avoidance is the number policy in our environment. Our modern pad mounted transformer are engineered and involves making it sit within a sealed. Our so called "tank-within-a-tank" guarantees that it can catch every leak to avoid from reaching the soil and groundwater. It will give the best layer of our protection in our environment.

The YAWEI Commitment: Engineering a Greener Grid

Sustainability cannot be optional, it should be the foundational design rules. YAWEI TRANSFORMER are committed to progressing our eco-friendly machines. Choosing a transformer with biodegradable fluids, 100% recyclable and can easily catch leaks means that you are making an investment on our product that not just reliable but also safer for our environment.